ACI CABIN PLASTICS

ACI is a UK based organization, providing solutions for cabin, cockpit, and cargo bay interior, components. Our global partnership with Future Metals gives you the delivery and service you deserve.

ACI provides solutions for cabin, cockpit and cargo bay interior components. Their in-house technical engineering team uses customer driven design and provides tailored solutions to deliver results.

Tube Products

Future Metals is globally recognized as an industry leader in the distribution of aircraft quality tubing. We carry a broad selection of aerospace tubing and aircraft quality tubing in stainless steel, titanium, aluminum and high temp alloys that are available in a variety of sizes and specifications. Get in touch with a member of our dedicated team for a personalized quote on your next aircraft grade tubing requirement.

Sheet Products

Future Metals is globally recognized as an industry leader in the distribution of aircraft quality bar, sheet, and tubing. We carry a broad selection of aerospace metals and aircraft quality materials in stainless steel, titanium, aluminum, nickel and high temp alloys that are available in a variety of sizes and specifications.

Our inventory is not just about quantity, but also, quality. Our team make sure that all the materials and process involved in the production are top notch and above industry grade.

Bar Products

Future Metals is a supplier and distributor of aircraft quality alloy bar products. We carry a large selection of aerospace alloy bar and aircraft quality bar in stainless steel, titanium, aluminum and high temp alloys that is available in a variety of sizes and specifications.

Get in touch with a member of our dedicated team for a personalized quote on your next aircraft quality bar requirement.

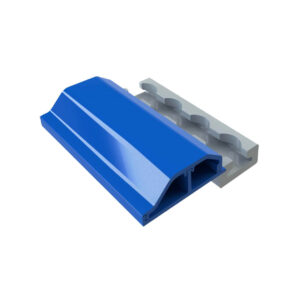

Aircraft Components, Extrusions, Roll Forms, Cabin Products

Future Metals is known as a global leader in the supply of aerospace extrusions, roll forms and seat tracks. If you are currently in search of the right aerospace extrusion or roll form for your project, then you’ve come to the right place. We carry a huge selection of aerospace and aircraft extrusions, roll forms and seat tracks for BAC (Boeing), AND (Army, Navy Drawings), LS (Lockheed) and many more.

Specialising in the utilisation and management of a large base of expert manufacturers. Airline Components International Ltd (ACI) offers capacity for volume production with options for low volume and bespoke items for our existing and new products or as ‘build-to-print’ against your or third party data.

Find the right aircraft extrusion, interior component, roll form, cabin product, or seat track for you here or get in touch with a Future Metals professional for more information and to receive a personalized quote on your next aerospace extrusion order.